The repair and overhaul process of heavy equipment has taken on greater importance as downtime of equipment is quite literally costing companies money in lost production. As overhaul turn-times shorten, cleanliness requirements have increased. An overhaul of the powertrain and other components is expected to last thousands of hours. Often the overhaul is scheduled based on the volume of diesel consumed in use. As in all industries today, there are increased customer expectations of the final product.

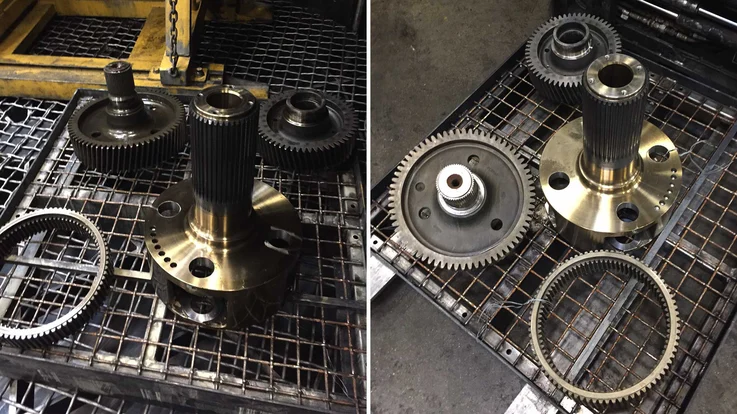

Parts degreasing occurs at various times in the overhaul process, the first being after tear down. Heavy grease, carbon, and oils need to be removed for further processing to occur. These “aged” soils can be challenging to remove from the part surface. Due to the size and quantity of components to be overhauled, large cabinet spray washers with 100-300 psi spray pressures are often utilized for the cleaning process.

It is common for the repair facilities to utilize powder degreasing products at 150 F or greater. These products generally contain 60-80% sodium hydroxide and other additives. Since the products are labeled as corrosive, care must be taken when working around these products due to the extremely high pH of 14. Because of the high volume of hydroxide, chemical streaking on the parts is very common. Hydroxides at these levels are difficult to rinse from the part surface. Lastly, this type of product is also known to create significant scale buildup on all washer surfaces and sludge in the wash bath as solubility of the powder can be difficult to accomplish. For EH&S reasons, repair facilities are now scrutinizing the use of these high pH products. They are looking for alternative chemistries that will meet ever-increasing cleanliness requirements and more favorable EH&S qualities.

Through testing, we have found that AquaVantage 3843 GD performs as well or better than the high pH powder chemistries. The 3843 GD is a blend of detergents, builders, and inhibitors. It has a mild pH of 11.9 as a concentrate. After the machine is drained, cleaned out, and descaled, the 3843 GD is added to the washer for use at 7-15%.

With the detergent technology available today, high pH, heavy hydroxide products are no longer required for parts degreasing in the overhaul of heavy equipment parts.